Warehouse Epoxy Flooring Systems Sydney

Durable, seamless and high-performance epoxy flooring systems designed specifically for warehouses, factories and industrial facilities across Sydney and NSW.

BENEFITS

- Seals and protects concrete and stops concrete dusting

- Aesthetically pleasing and professional-looking

- Exceptionally strong, built to withstand forklifts and large machinery

- It brightens the surface and improves safety

- Resists chemical spills and oils

Industrial Epoxy Flooring for Warehouses & Distribution Centres

Warehouse epoxy flooring provides a tough, non-porous surface that protects concrete from heavy traffic, forklifts, pallet jacks, chemical spills and daily wear.

Our systems are commonly installed in:

- Warehouses and logistics centres

- Manufacturing and production facilities

- Cold storage and food processing areas

- Workshops and bulk storage facilities

We service Sydney metro, Western Sydney, Inner West, South West Sydney, Central Coast and surrounding NSW regions.

Please scroll to the bottom of the page to view images of our finished projects in various systems and colour schemes.

Why Epoxy Flooring Is Ideal for Warehouse Environments

DustproofingEpoxy flooring seals the concrete surface, eliminating concrete dusting and creating a clean, easy-to-maintain warehouse floor. | Aesthetically Professional FinishA smooth, seamless epoxy finish improves the appearance of warehouse floors while creating a brighter, more organised working environment. | Built for Heavy Traffic & ForkliftsHigh-performance epoxy systems provide long-term protection against wear and abrasion, extending the life of warehouse concrete floors. | Slip and chemical-resistantAnti-slip additives and chemical-resistant coatings reduce slip hazards while protecting floors from oils, fuels and chemical spills. | Customisable for Warehouse OperationsEpoxy floors can be customised with safety line marking, walkways, colour zoning and exclusion zones to suit operational and compliance requirements. |

Durability and longevityIndustrial epoxy floors are built to withstand constant forklift movement, heavy loads and impact without cracking or surface breakdown.

| Long-Term Cost EfficiencyEpoxy flooring lasts significantly longer than standard concrete sealers, reducing maintenance, repairs and downtime over time. | Seamless & Hygienic SurfaceWith no grout lines or joints, epoxy flooring improves hygiene standards and makes cleaning faster and more effective. | Improved Light Reflection & VisibilityLight-coloured epoxy coatings reflect light, increasing visibility and improving overall workplace safety. | Low maintenance requirmentsEpoxy floors require minimal ongoing maintenance, helping reduce cleaning time, repair costs and operational disruption. |

Warehouse Epoxy Flooring Systems We Install

We install a range of industrial epoxy flooring systems to suit different warehouse environments, traffic levels and operational requirements. Each system is selected based on site conditions, forklift traffic and expected wear.

Two-Coat Epoxy Flooring System A cost-effective epoxy flooring system designed to seal concrete, eliminate dusting and improve durability in warehouses with light to moderate traffic. Best for: Ligh to medium-duty warehouses and storage areas

|

|

Three-Coat Epoxy Flooring System A more robust epoxy flooring system that provides increased thickness, strength and wear resistance for warehouses with regular forklift traffic. Best for: Medium to high-traffic warehouses and distribution centres

|

|

High-Build / Heavy-Duty Epoxy Flooring System A high-performance epoxy flooring system engineered for demanding warehouse and industrial environments with heavy machinery, constant traffic and high wear conditions. Best for: Heavy-duty warehouses, manufacturing facilities and industrial environments

|

|

Our Warehouse Epoxy Flooring Application Process

Every warehouse epoxy flooring system is installed using a proven preparation and application process to ensure maximum adhesion, durability and long-term performance. The exact system thickness and number of coats will vary depending on site conditions and operational requirements.

Step 1: Surface Preparation

Concrete surfaces are diamond ground or shot blasted to remove contaminants, open the surface and create the correct profile for epoxy adhesion.

Step 2: Crack Repairs & Surface Levelling

Cracks, joints and surface imperfections are repaired using epoxy fillers and mortars to create a smooth, uniform base.

Step 3: Epoxy Priming

Specialised epoxy primers are applied to penetrate the concrete and ensure strong bonding between the slab and the epoxy system.

Step 4: Epoxy System Application

The selected epoxy flooring system is applied in multiple coats to achieve the specified thickness and performance level for the warehouse environment.

Step 5: Anti-Slip & Safety Finishes (If Required)

Slip-resistant additives, safety line marking and colour zoning are installed where required to improve safety and operational efficiency.

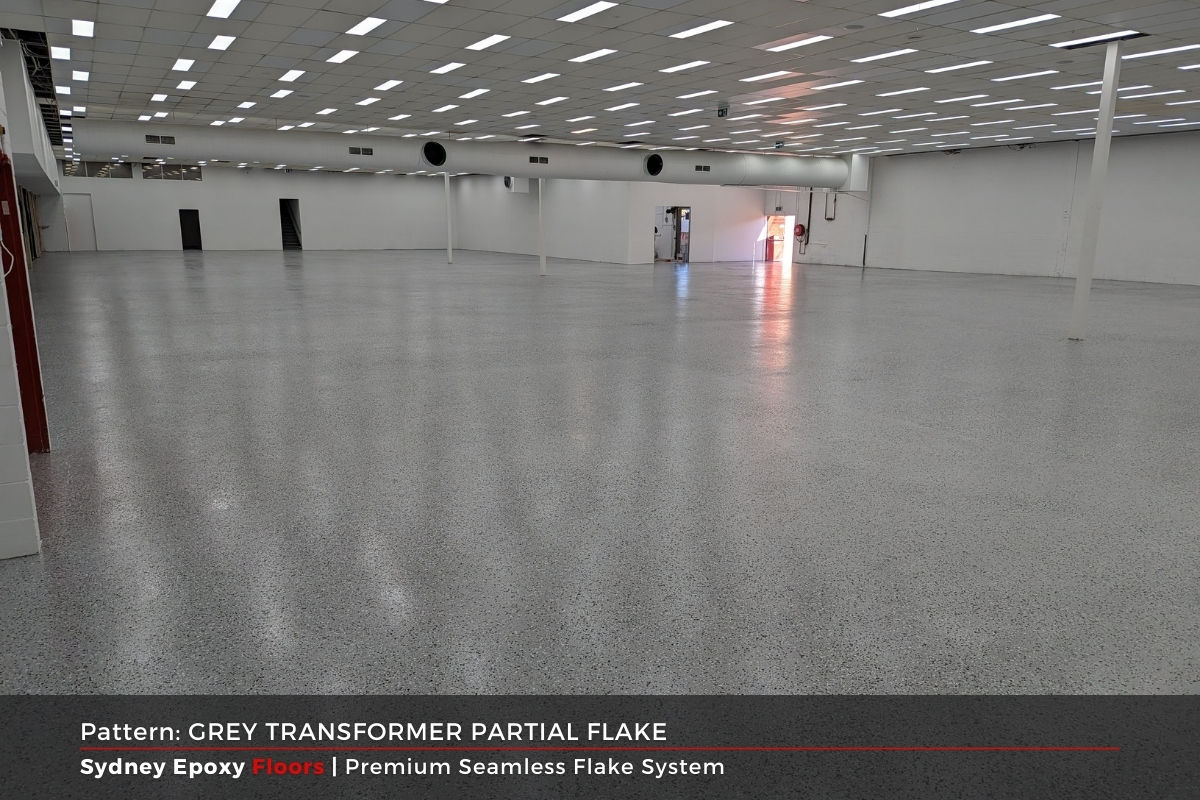

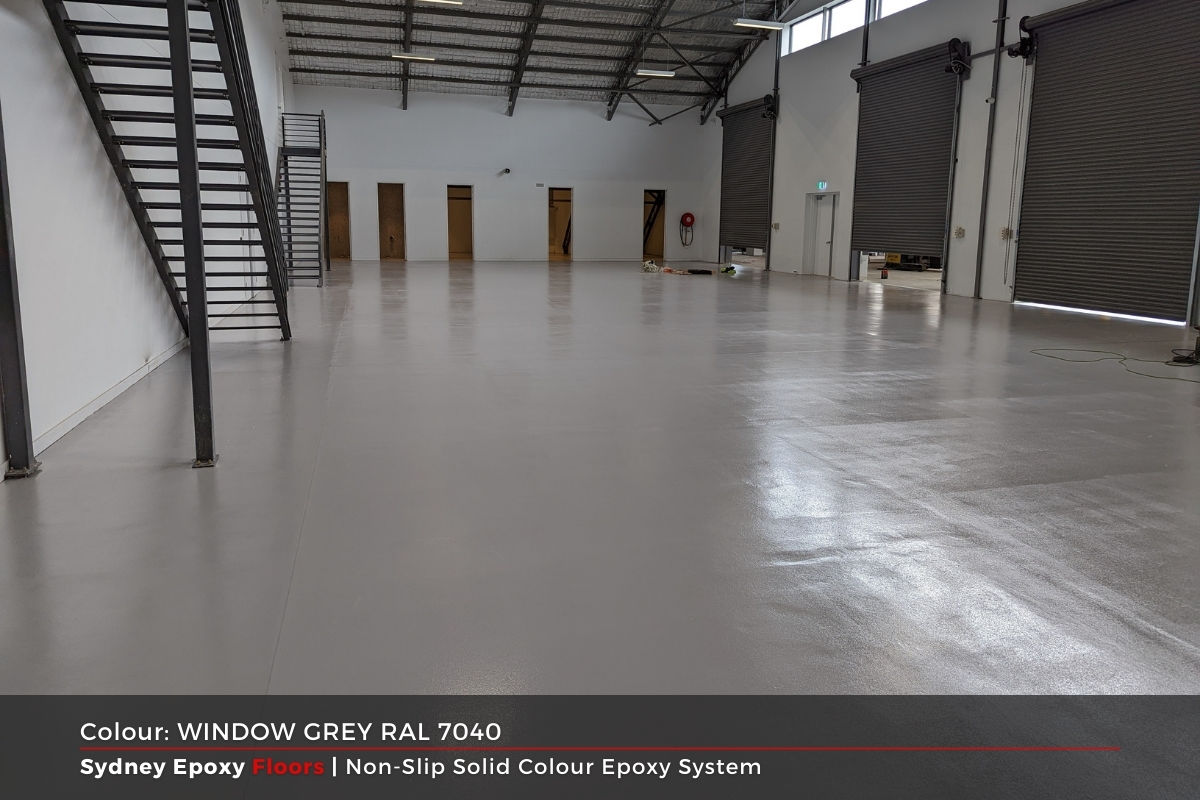

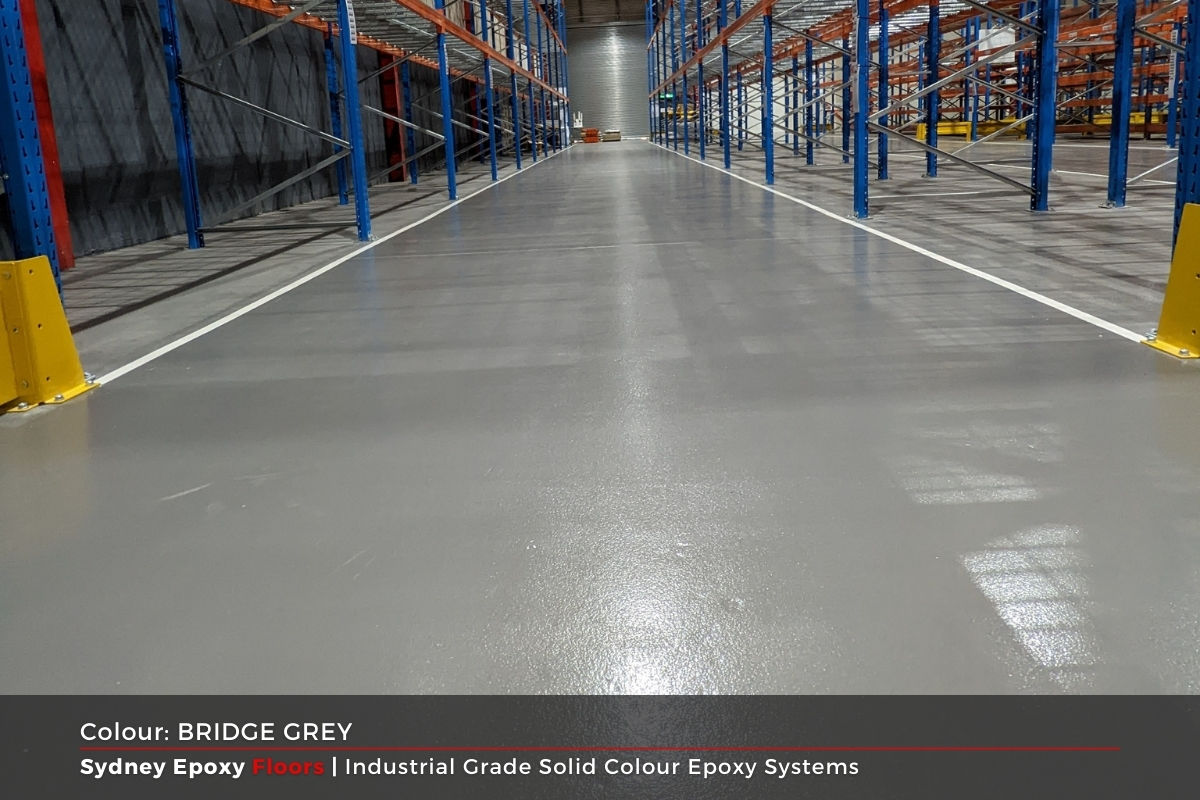

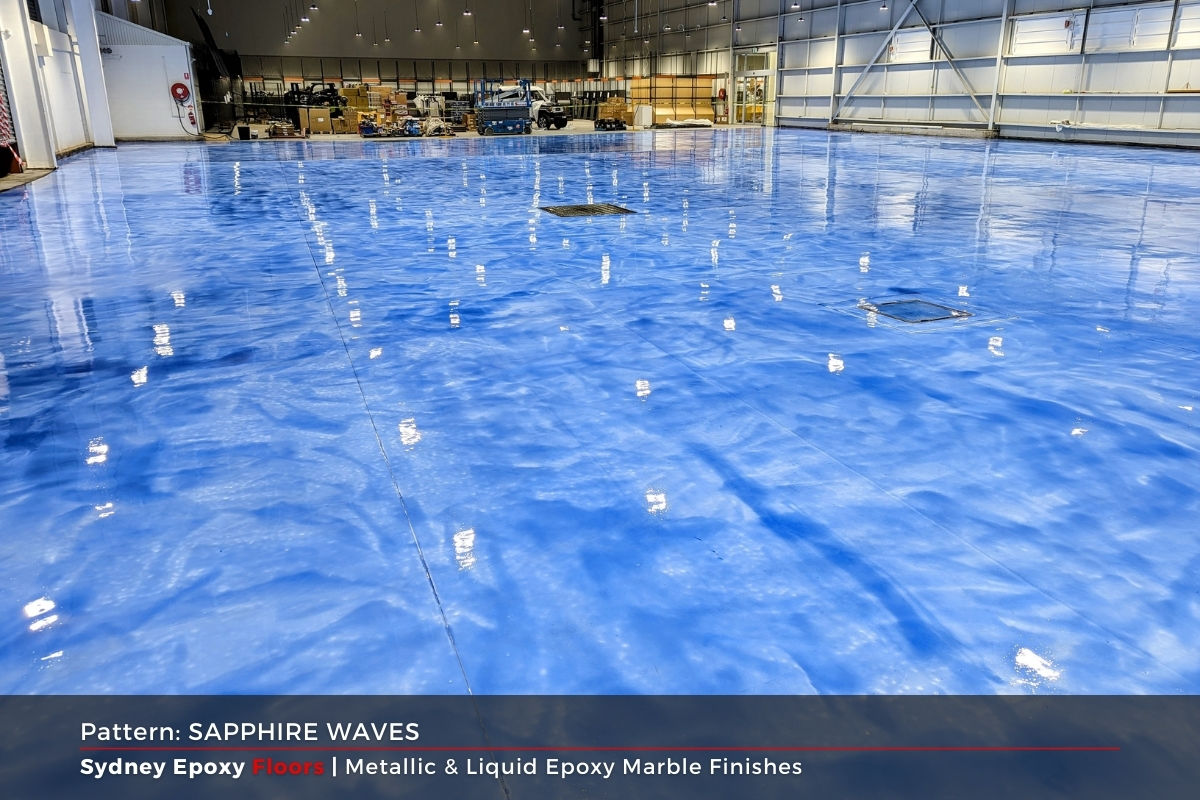

Photos of our completed warehouse epoxy flooring projects

|  |  |  |

|  |  |  |

|  |  |  |

|  |  |  |

|  |  |  |

All Your Warehouse Epoxy Requirements

Contact our office today to arrange for a tailor-made quote for all your warehouse epoxy flooring requirements. Alternatively, visit our Sydney Epoxy showrooms located at 6 Giffard Street Silverwater NSW 2128 or 283 Victoria Road Rydalmere, NSW 2063 to see the variety of finishes painted on our floors.