Warehouse Epoxy Flooring Contractors Servicing Sydney, Wollongong, Central Coast, Newcastle and Blue Mountains.

BENEFITS

- Seals and protects concrete and stops concrete dusting

- Aesthetically pleasing and professional-looking

- Exceptionally strong, built to withstand forklifts and large machinery

- It brightens the surface and improves safety

- Resists chemical spills and oils

Why is epoxy flooring is the most suitable solution for warehouse floors?

Epoxy flooring has emerged as the go-to solution for warehouse spaces due to its unparalleled durability, resistance, and aesthetic appeal. When it comes to outfitting your warehouse with epoxy flooring, selecting the right product is paramount to ensuring long-term performance and minimal maintenance. In this guide, we'll explore two top-tier epoxy flooring products renowned for their reliability and effectiveness: Sikafloor 264 and Ultrakote's Ultrashield.

Warehouse epoxy flooring provides a protective, durable, and aesthetically appealing solution for the busy environment of a warehouse. It is designed to be incredibly hard-wearing, not only providing protection for the surface below but also an easy-to-clean top layer with excellent resistance to scuff marks and abrasions. In addition to being highly scratch-resistant and slip-resistant, warehouse epoxy flooring can also enhance safety levels by including features such as anti-static, fire-retardant coatings, or specialised drainage systems built into the design. An epoxy floor system can provide long-term protection while offering affordable maintenance costs and savings in labour and repair. This makes it an ideal choice for warehouse managers looking to improve hygiene, reduce downtime, and improve their working environment.

Please scroll to the bottom of the page to view images of our finished projects in various systems and color schemes.

Benefits of applying epoxy flooring to your warehouse floor

| Dustproofing Epoxy flooring is a long-term substitute for concrete dusting and offers a surface that is simple to sweep or mop to keep it looking clean and fresh. A lighter-colored warehouse floor coating produces a bright surface, enhancing efficiency and safety while decreasing energy expenses. | Aesthetically pleasing Warehouse epoxy flooring will improve the overall appearance of a warehouse and provide professional work envirnmnet Epoxy resins are available in a variety of colours and finishes, allowing you to select the style that best suits your environment. | Durability and longevity Epoxy flooring is known for its durability and resistance to damage. It can withstand heavy foot traffic, as well as the weight of forklifts and other equipment commonly found in warehouses. Properly applied resin flooring can last up to 10 years before it requires re-coating. | Slip and chemical-resistant Warehouse epoxy flooring materials are chemical resistant and can be made slip-resistant by adding the appropriate antislip media, making it safer for personnel and visitors while not compromising on making it a difficult surface to clean. |

Useful Information about warehouse epoxy flooring

Warehouse floors are not a good fit for all epoxy flooring products. A specific epoxy floor coating solution is required for warehouse floors in order to survive heavy vehicle traffic, including forklifts and trucks, product spills, and frequent mechanical cleaning. Selecting flooring that is inappropriate for a warehouse setting carries the following risks:

Our Sydney Epoxy Floor Warehouse epoxy flooring systems can be applied over a weekend to minimise disturbance to your business schedule and offer an incredibly durable, safe surface for personnel and forklifts to operate on. Warehouses equipped with automated guided vehicles (AGVs) can greatly benefit from the application of high-build, self-leveling epoxy flooring systems. We specialize in the preparation and application of smooth coatings over both new and old slabs, and we guarantee that the floor coating will satisfy AGV requirements. Contact us today to arrange for a free site measurement and quote. | Move the white slider below to view our Premium Epoxy Flake Flooring transformation! |

Here are our three most common warehouse epoxy flooring systems

Two coats epoxy flooring system achieving a total dry film thickness (DFT) of 300 microns (0.3mm).Sydney Epoxy Floors' two coats epoxy flooring system is one of the most popular and cost-effective coating solutions. Two roll coats of coloured epoxy allow you to customise your surfaces while getting the required protection without breaking the bank. Two coats of solid-color epoxy system is a preferred choice for warehouses, storage units, loading docks, and carparks. The cost-effectiveness of this system makes it a favorite among industrial property owners looking for long-lasting results with minimal investment.

|

|

Three coats epoxy flooring system applied achieving a dry film thickness of 1000 microns (1mm).Sydney Epoxy Floors' three coats warehouse epoxy flooring system is ideal for damaged warehouse floors that have medium to high usage - the self-leveling properties of our SEF100-EPSL epoxy flooring primer will allow the primer to flow and fill in any minor imperfections and cracks and end results will be smoother than the roll coats system and it will last up to two times longer than the roll coat floor coating system. This system can last up to 7 years in warehouses with medium to high activity and up to 10 years in warehouses with light to medium traffic on the floor.

APPLICATION STEPS

|

|

Three coats epoxy flooring system applied achieving a dry film thickness of 3–5 mm depending on the project's requirements.Sydney Epoxy Floors' ultra high build warehouse epoxy flooring system is an excellent choice for highly damaged warehouse floors or warehouses with a high volume of traffic, such as AGV (Automated Guided Vehicles/Forklifts). The SEF Three coats, floor coating system consists of three coats of 100% solids epoxy resin applied over an existing coating or bare concrete floor, with the dry film thickness adjustable to meet the needs of your floor. This system can give 10+ years of service in high-traffic warehouses.

APPLICATION STEPS

|

|

DO IT YOURSELF & SAVE! |

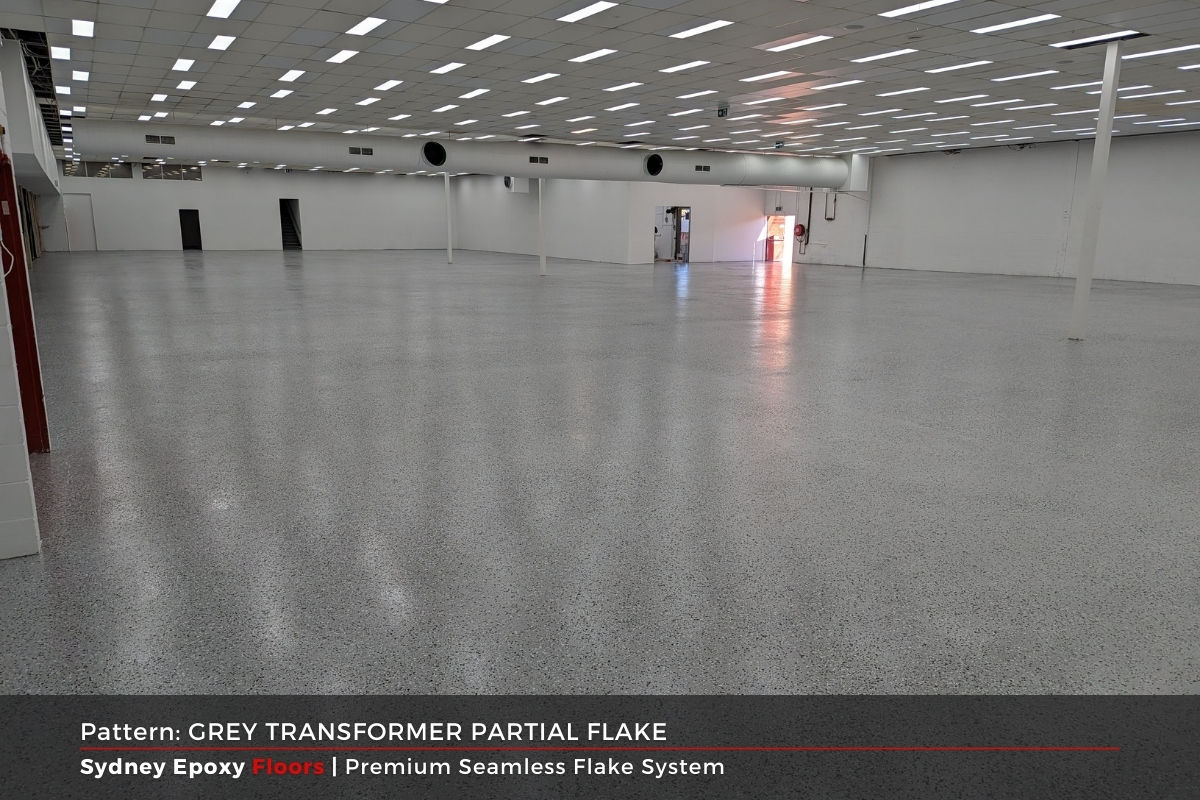

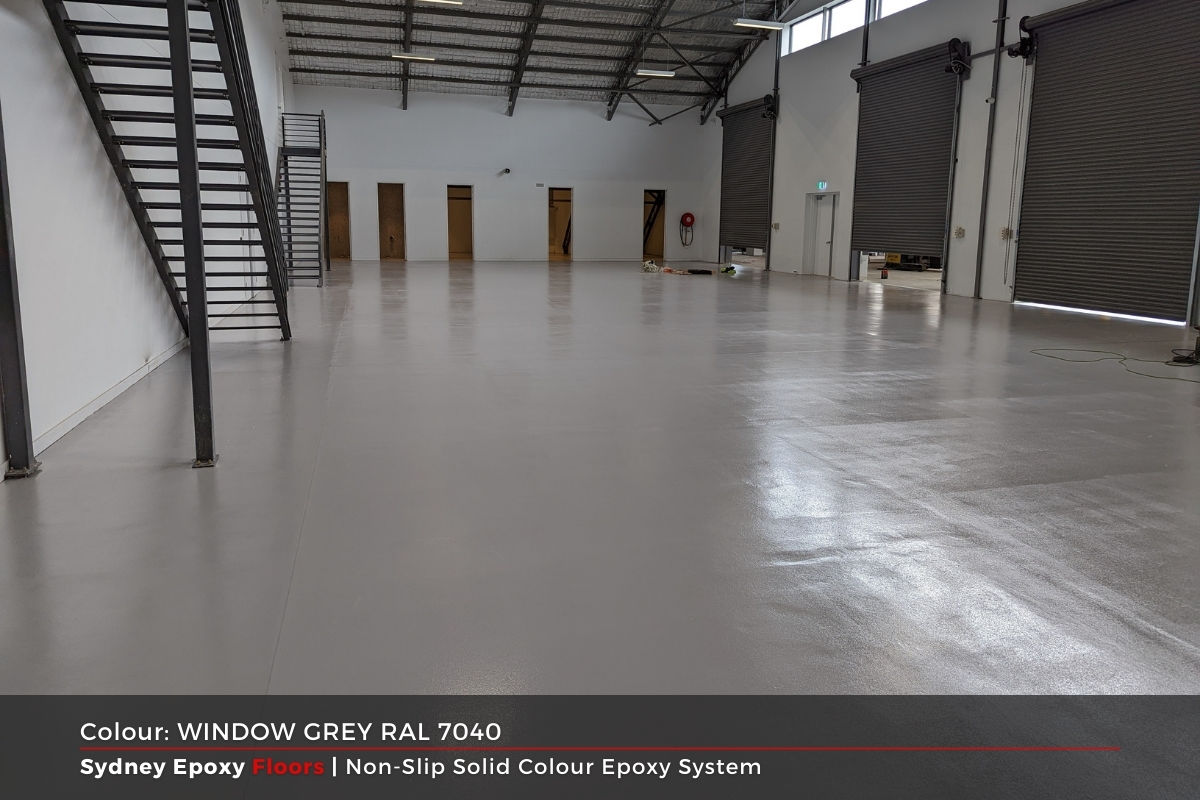

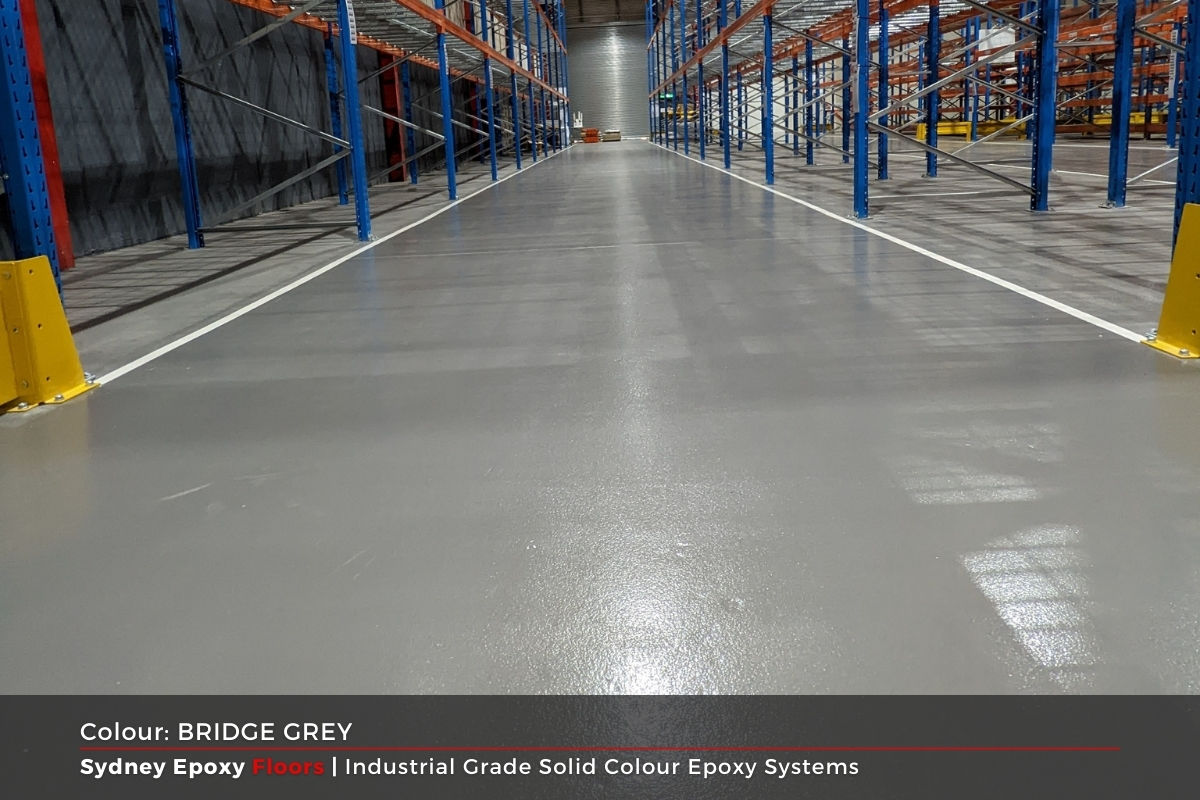

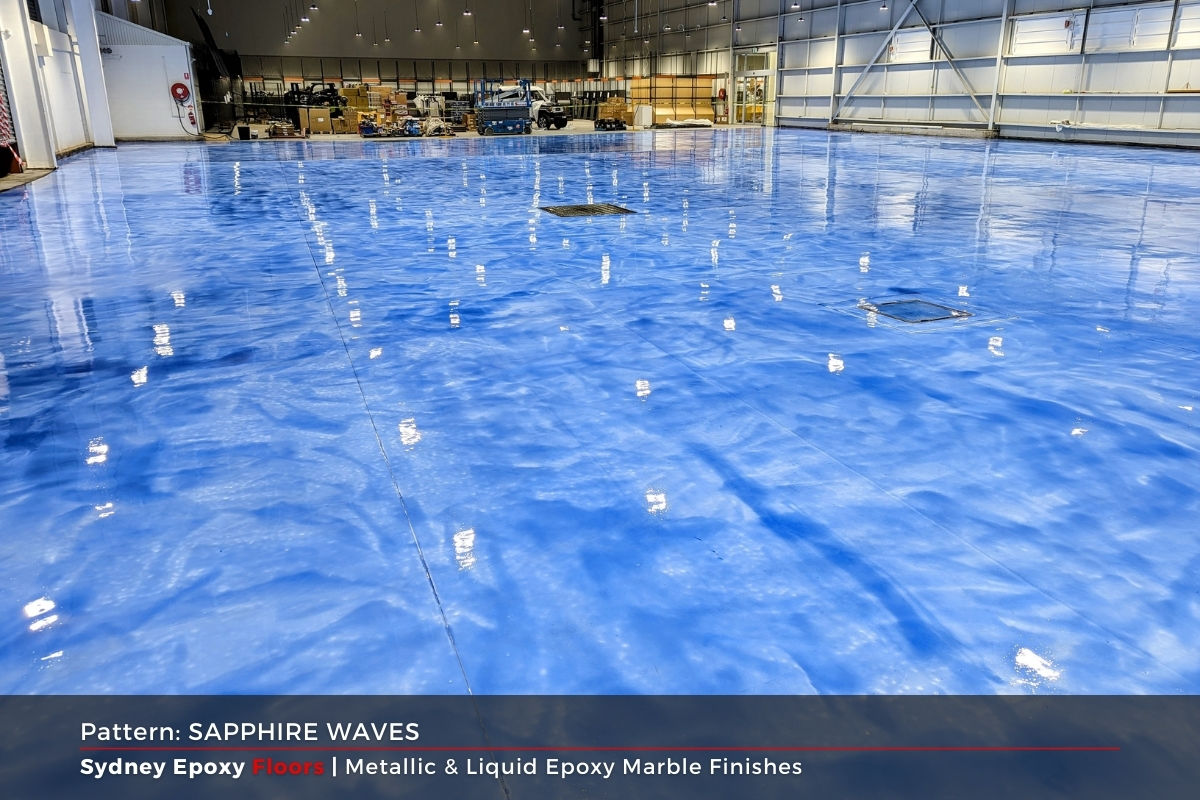

Photos of our completed warehouse epoxy flooring projects

|  |  |  |

|  |  |  |

|  |  |  |

|  |  |  |

|  |  |  |

All Your Warehouse Epoxy Requirements

Contact our office today to arrange for a tailor-made quote for all your warehouse epoxy flooring requirements. Alternatively, visit our Sydney Epoxy showroom located at 6 Giffard Street Silverwater NSW 2128 or 153 Sailors Bay Road Northbridge, NSW 2063 to see the variety of finishes painted on our floors.